Manufacturing ERP Buyer's Guide

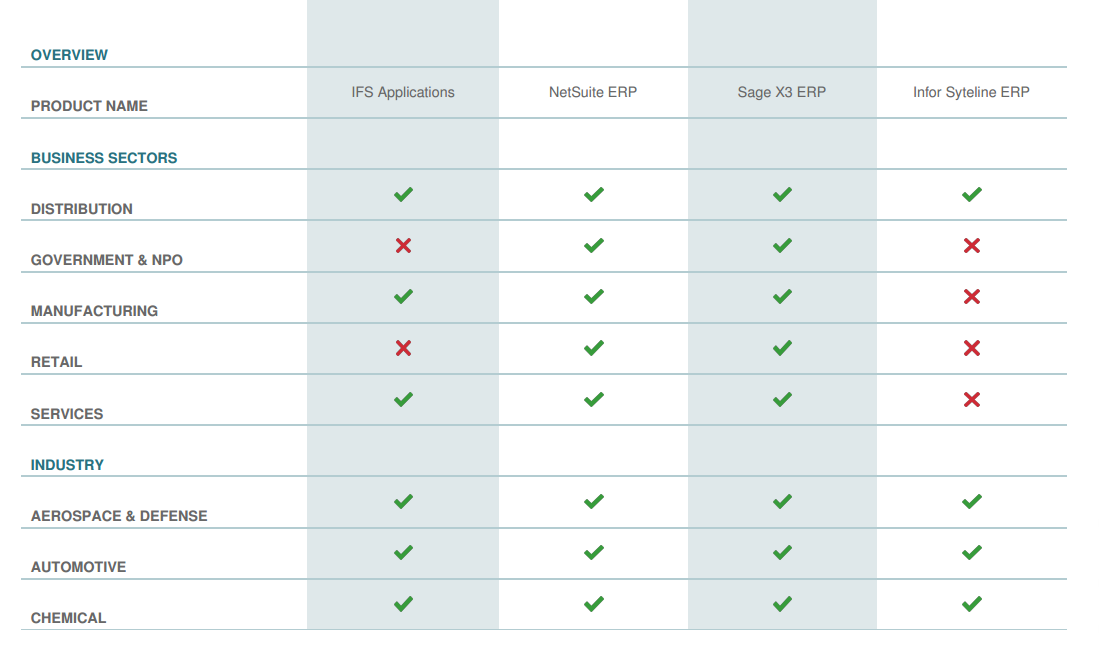

This list of top manufacturing ERP software systems offers over 100 options for businesses. With many options available, it’s crucial to choose an ERP that aligns with your manufacturing needs. Here’s a look at some popular choices:

- SAP Business One helps small and medium-sized businesses to manage core business processes.

- PLEX was developed specifically for manufacturing, delivering a unified, shop-floor-to-top-floor ERP solution.

- QAD Adaptive ERP provides a comprehensive, adaptive solution supporting global manufacturing operations.

Every one of these ERPs is a robust solution. But how do you choose the best ERP for your manufacturing business among so many excellent options?

Identifying your requirements for a manufacturing ERP

The starting point for selecting the right ERP is understanding your business’s unique requirements. Ask yourself:

- What specific challenges is your current system failing to address?

- What capabilities are essential for meeting customer expectations?

- Are there processes you’d like to streamline but are held back by limitations in your current tools?

These are enterprise-level questions, so get people from across all the disciplines within your business. Ensure everyone has a shared understanding of ERP systems, how they work, and what one can expect from ERP. Language and communication are important.

Each team should list their specific ERP requirements. For instance, production engineering may need features that differ from those of sales. At this stage, every idea is worth considering.

Examine each item carefully and see if some rewording can update that production engineering one to include the outside sales item. You might find a seemingly unrelated item on accounting’s list can now be incorporated. Keep in mind this is an enterprise activity and you might toss out some wishes that have limited benefits but are not truly a benefit to the entire business.

Take the second draft of your requirements list to those who weren’t part of your initial team. Think of all the employees and associates who will use or be affected by your choice of ERP. Some of your items might be less important than you originally thought and some new items no one considered are now listed.

Defining “must-haves” vs. “nice-to-haves”

Rank the refined requirements list. Define your top priorities – those without which the ERP system would fail to meet your core business needs. These are your “must-haves.”

Below these, list your “nice-to-have” features—valuable but not essential. Any ERP system that does not meet all must-have requirements can be eliminated from your consideration. With this refined list, you can narrow down the pool of ERP options to those that best align with your business needs.

Top features to look for in a manufacturing ERP

- Modular design:

Many ERPs offer individual modules tailored to specific business functions. For instance, discrete manufacturers can focus on discrete manufacturing modules rather than paying for unnecessary process modules. - Real-time data:

A critical feature of manufacturing ERP software is real-time data processing. Immediate updates enable seamless coordination across departments. For instance, when received inventory is automatically reflected across production, purchasing, and accounting. - Customer Requirements Management (CRM):

Integrated CRM capabilities allow manufacturers to track customer relationships, quotes, and sales orders easily. CRM insights into profitable accounts, order histories, and customer preferences drive improvements in customer service and operational focus. - GAAP compliance:

Manufacturing ERP systems must comply with Generally Accepted Accounting Principles (GAAP) and local regulations. The right ERP ensures financial data is aligned with accounting standards, easing regulatory compliance. - Work in Process (WIP) tracking:

WIP tracking is vital for understanding inventory and production costs. Manufacturing ERPs provide a detailed view of inventory in various stages of completion, allowing for accurate financial and operational insights. - Manufacturing operations management:

ERP software for manufacturing should include tools for managing bills of materials, production routing, and workflows. These tools support efficient production processes and inventory management, whether for discrete or process manufacturing. - Business Intelligence (BI):

Business intelligence is essential for data-driven decision-making. Dashboards and reporting features provide real-time insights, enabling executives to make proactive decisions based on current data trends and performance indicators.

How much does an ERP for manufacturing cost? How much should you budget?

The cost of manufacturing ERP systems can vary from free open-source solutions to multimillion-dollar enterprise systems. Keep in mind that initial setup costs are just one part of the investment. Ongoing costs, including maintenance, training, and upgrades, are crucial to budget for as well.

Open-source ERP solutions might offer free initial access but require in-house expertise for support and customization. Alternatively, cloud-based ERP solutions, often billed monthly, provide lower upfront costs and include security, updates, and support in the subscription.

When budgeting, weigh the initial investment against the total cost of ownership, which includes support, hardware, and personnel required to maintain the ERP system.

Selecting the best manufacturing ERP in 2026

Among the top manufacturing ERP systems are solutions from industry leaders like SAP, Oracle and Microsoft Dynamics 365. Each offers comprehensive features, but the best choice will depend on your unique requirements. For smaller manufacturers, solutions like Microsoft Dynamics 365 Business Central provide affordable, scalable ERP options tailored to growth.

To select the best ERP for your manufacturing business in 2026

- Build your initial manufacturing software shortlist using our comparison engine

- Review product features listed on vendor sites and explore reviews for user insights.

- Read ERP analyses in trade journals.

- Request demonstrations from vendors of your top choices to see the software in action.

The ERP selection process is iterative but valuable. By gathering insights across departments and consulting industry peers, you’ll find an ERP solution tailored to your manufacturing needs.

Good luck with your ERP selection!