Food and Beverage ERP Buyers' Guide (2026)

Food manufacturing and distribution companies encounter unique challenges that set them apart from other industries. To tackle these obstacles effectively, selecting an ERP solution tailored to your needs is crucial. However, with so many options available, knowing where to begin can feel overwhelming.

That’s where we come in. This guide, based on insights from industry professionals and project managers, simplifies the ERP software selection process for food and beverage businesses.

It will help you address critical questions, such as:

- What features should you prioritize in a food manufacturing ERP?

- Which food and beverage ERP solutions should you consider?

- What are the associated costs, and how can you budget effectively?

Key business challenges in food ERP selection

The food manufacturing ERP software selection process must consider a range of industry-specific challenges. To stay competitive and compliant, these issues must be addressed through your ERP system. Some of the most pressing challenges include:

- Compliance and traceability: The food industry is heavily regulated to ensure product safety. ERP solutions must facilitate full traceability, including bidirectional tracking across the supply chain.

- Speed and shelf life management:

- Inventory turnover is crucial for perishable goods. Your ERP should optimize production scheduling and warehouse management to reduce waste.

- Lot tracking and recalls: Whether it's fresh produce or packaged goods, effective ERP solutions provide end-to-end traceability to ensure quick and efficient recalls if necessary.

When building a list of requirements for your ERP, it’s essential to keep these factors in mind. This is just the tip of the potential ERP selection iceberg, so it's worth spending some time on - use this guide to selecting process manufacturing ERP to ensure you’re doing it right.

Industry-specific ERP considerations

Generic food manufacturing ERP software might not suit every business. You need a system tailored to your specific operational needs. Here are a few key factors to consider:

- Software fit for food processing: Your ERP must support multiple processing steps, catchweight functionality, and raw material variability (e.g., different cuts, by-products). Sales and inventory management should account for both discrete units (cases) and weight-based pricing.

- Freshpack, cannery, and growers: Lot tracking must align with the Product Traceability Initiative, grower accounting, and co-product management for repack operations.

- Bakeries and frozen goods: Managing recipes, batch scaling, and demand forecasting are essential for businesses dealing with perishable goods and dynamic route management in direct store delivery (DSD).

- Private-label food processors: Frequent reformulations require an ERP that enables rapid product development and easy scaling to ensure seamless recipe management.

- Food packaging: Ensure your ERP supports packaging line integrations, material requirements planning (MRP), and compliance with food safety standards. Accurate labeling and traceability features are crucial for regulatory compliance.

Across all food segments, compliance is paramount. Your ERP for food manufacturing must support FDA, BRC, SQF, HACCP, and FSMA standards while ensuring effortless adaptation to evolving regulations.

Which compliance requirements should a food ERP system help me hit?

In the U.S., the two major regulatory bodies overseeing food safety are the Food and Drug Administration (FDA) and the Environmental Protection Agency (EPA). A good food ERP system should help your business meet key compliance initiatives from these organizations:

- HACCP (Hazard Analysis and Critical Control Points): Identifies potential hazards in the production process and establishes control measures to minimize risks.

- FSMA (Food Safety Modernization Act): Requires each facility to develop a comprehensive food defense plan.

- CGMP (Current Good Manufacturing Practices): Ensures the quality of processed foods and dietary supplements by maintaining standards for production and handling.

For further details, check out our food manufacturing compliance checklist.

Which features does food ERP need?

A comprehensive food ERP should go beyond basic functionalities like financial management and accounting. To truly support your business, an ERP designed for the food and beverage industry should offer features tailored to your specific operational needs.

Core features include:

- Recipe management: This is essential for automating recipe formulation and handling unit conversions (e.g., converting lbs to kg). A good recipe management system can also adjust

- Lot tracking: Bidirectional tracking is crucial for traceability and compliance, allowing you to quickly manage recalls in case of a safety issue.

- Inventory optimization: This should include advanced functionalities such as put-away rules based on product type (e.g., allergens or kosher items), picking and packing efficiency, and integration with the shop floor.

Advanced features:

- Coproduct and byproduct management: Many food manufacturing processes yield coproducts (byproducts that can be sold in secondary markets). A strong ERP system can manage these efficiently, turning potential waste into additional revenue streams.

- Catchweight functionality: In situations where exact measurements are difficult (such as unpackaged meat or produce), catchweight capabilities help convert inexact units into precise, usable inventory.

- Extended Warehouse Management System (WMS) functionality: A fully-featured WMS enhances your ability to reduce human error and prevent spoilage by optimizing storage and handling processes.

For more functionality to consider during your requirements-gathering phase, check out this guide to 70 ERP features to consider for your next software purchase.

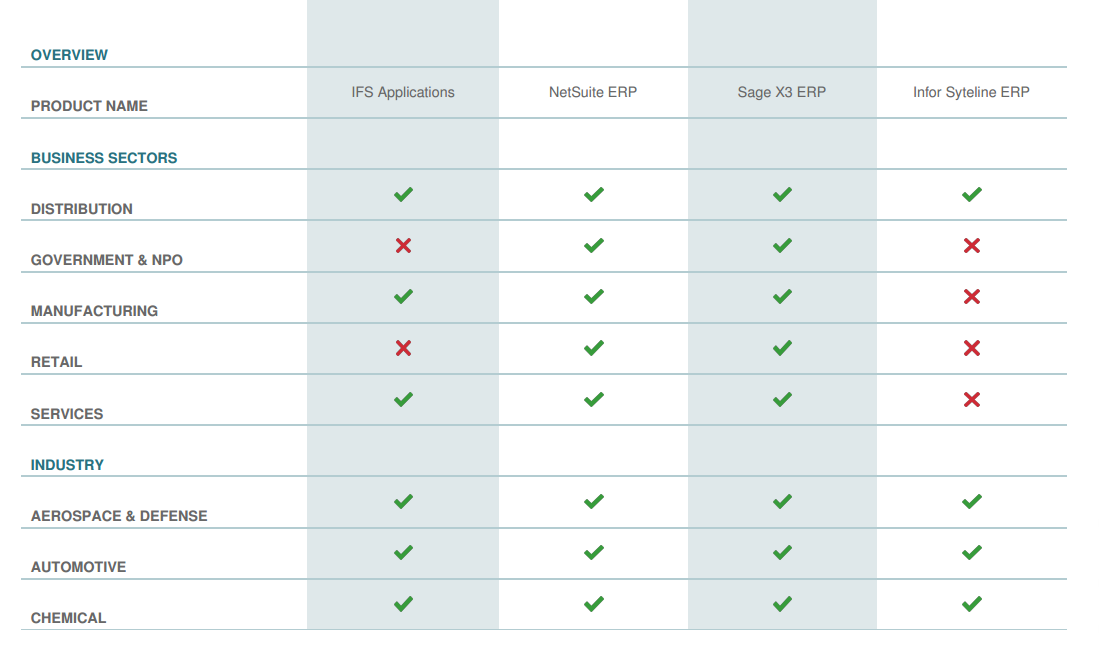

Which food ERP vendors should I consider?

Many vendors offer ERP for the food industry. Some of these are specifically designed for food or process manufacturing companies; others are general-use ERPs that can be customized to food-specific processes.

We profile a few of the most prominent below, but you can find an extensive comparison of ERP providers that sell into the food manufacturing and distribution industries here.

- ProcessPro ERP: Ideal for small and medium-sized batch process manufacturers, ProcessPro offers recipe management, lot traceability, and quality control, all key features for food manufacturing.

- Aptean JustFood ERP: Designed for companies of all sizes, JustFood offers flexibility with both on-premise and cloud-based solutions. It’s particularly well-suited for businesses transitioning from smaller systems like QuickBooks.

- DEACOM ERP: This standalone ERP is built for multi-geographic batch or process manufacturing needs and is commonly used by larger enterprises. Its comprehensive inventory management and traceability features make it a top choice for food manufacturers.

- Aptean Ross ERP: Aptean’s process manufacturing-specific offering is used by process manufacturers of all sizes who need a flexible on-premise solution. Ross is modular, meaning that users can add functionality as and when they require it. The ‘Trace Express’ module provides comprehensive forward and backward trace and product recall functionality.

- bcFood ERP: Built on Microsoft Dynamics NAV, bcFood is designed specifically for food manufacturers. It expands on NAV’s core ERP features with quality control, recipe definition, and advanced notification features.

Each vendor brings something unique to the table, so it’s essential to match the ERP’s strengths to your company’s specific needs.

How much does food ERP cost, and how should you build a budget?

It’s not easy to put an exact figure on how much a food ERP should cost you.

WorkWise (now under Aptean) estimates that the total cost of selecting and implementing an ERP could fall anywhere between $75,000 to $750,000 for a small to medium-sized business.

As a start, you can use this ERP pricing guide to gather some baseline costs for a number of ERP systems. Here are a couple of examples from vendors who provide food-specific solutions:

- ProcessPro: From $999 per month (unlimited users)

- Epicor Tropos: From $150 per user, per month

- DEACOM: $7000 per user (perpetual license)

Beyond software licensing, additional costs to consider include:

- New hardware (particularly for on-premise solutions)

- Extra staffing requirements during implementation (including staff overtime and external temporary staff like consultants)

- Staff training

- Any extra support costs agreed with your vendor